QUALITY ASSURANCE

At Metco Industries, quality is at the core of everything we do. Our Quality Department is built around a highly trained and well-equipped team dedicated to exceeding customer expectations. Every customer as unique requirements, and our success comes from meeting and often surpassing those needs with precision and consistency.

Through continuous training, investment in state-of-the-art inspection equipment, and a commitment to innovation, Metco Industries ensures every powder metal component meets the highest industry standards. Our Quality Management System is audited annually by an independent third party, maintaining full certifications to ISO 9001:2015 and IATF 16949:2016.

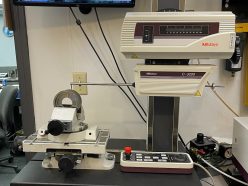

Inspection & quality control Equipment

To guarantee precision and repeatability, Metco Industries utilizes advanced inspection and testing equipment including:

- 7 Coordinate Measuring Machines

- 3 Optical Video Inspection

- 5 Optical Comparator

- 3 Laser Micrometer

- 5 Rockwell Hardness Tester

- Carbon Analyzer

- 3 Universal Compression/Tensile Machines

- Double Flank Gear Roll Tester

- Cylindrical Testing

- Roundtest, Flatness and Runout

- Contracer Form Measurement Machine

Our powder metal control process begins at the blending stage and continues through every production step. All orders are carefully monitored, ensuring traceability, consistency, and superior results.

Metco Industries continuously evaluates and upgrades inspection systems based on new part requirements and continuous improvement initiatives. This commitment to technology and quality ensures our customers receive reliable, high-performance powder metallurgy components.

Design & ENGINEERING EXCELLENCE

Metco Industries maintains a strong in-house design and Engineering Department focused on helping customers achieve their performance and cost goals. Using Creo/Pro Engineer and Solid Edge software, our team provides design assistance, prototype development, and engineering support for all applications.

By integrating design and quality early in the process, we help customers reduce lead times, improve manufacturability, and achieve optimal part performance.

CUSTOMER-FOCUSED SALES SUPPORT

Our Sales Department is driven by customer service and backed by extensive manufacturing and engineering experience. From the first quote to final delivery, Metco Industries works closely with customers to ensure that all technical and quality requirements are met.

QUALITY CERTIFICATIONS

ISO 9001:2015 Certification of Registration:

Metco Industries, Inc. has been assessed by NQA and found to be in conformance to ISO 9001:2015

You can view the certificate here

IATF 16949:2016 Certification of Compliance:

Metco Industries, Inc. has been assessed by NQA and found to be in conformance to IATF 16949:2016.

You can view the certificate here.

VP of Quality & Engineering

Jim Wimer

814-781-3630 Ext. 223

814-594-2011 Cell

CONTACT OUR QUALITY TEAM